Pneumatic actuator “SIRCA” AP Series (หัวขับลมสำหรับติดตั้งวาล์ว)

ช่องทางสั่งซื้อออนไลน์ (ออกใบกำกับภาษีทุกช่องทาง)

สินค้ารายการดังกล่าวยังไม่รองรับการสั่งซื้อผ่าน Shopee หรือ Lazada โปรดติดต่อเจ้าหน้าที่ Line: @pakoeng

เอกสารประกอบ

*เนื่องจากสินค้าบางรายการของทางบริษัท จำเป็นต้องระบุรายละเอียดหลายขั้นตอน สอบถามรายละเอียดได้ที่ sales@pako.co.th

เพิ่มเพื่อนขอใบเสนอราคาได้ที่ LINE Official : @pakoeng

SIRCA | AP Series | Pneumatic actuator

PNUEMATIC-ACTUATOR “SIRCA” AP-Series ได้รับการออกแบบมาโดยเฉพาะเพื่อตอบสนองความต้องการของคุณในตลาดวาล์วอัตโนมัติ เราสามารถจัดหาแรงบิดเอาต์พุตได้หลากหลายเพื่อให้เหมาะกับบอลวาล์ว , บัตเตอร์ฟลาย สำหรับโซลูชั่นระบบอัตโนมัติของวาล์วที่สมบูรณ์

Technical features Pneumatic Actuator Ap0 – AP12

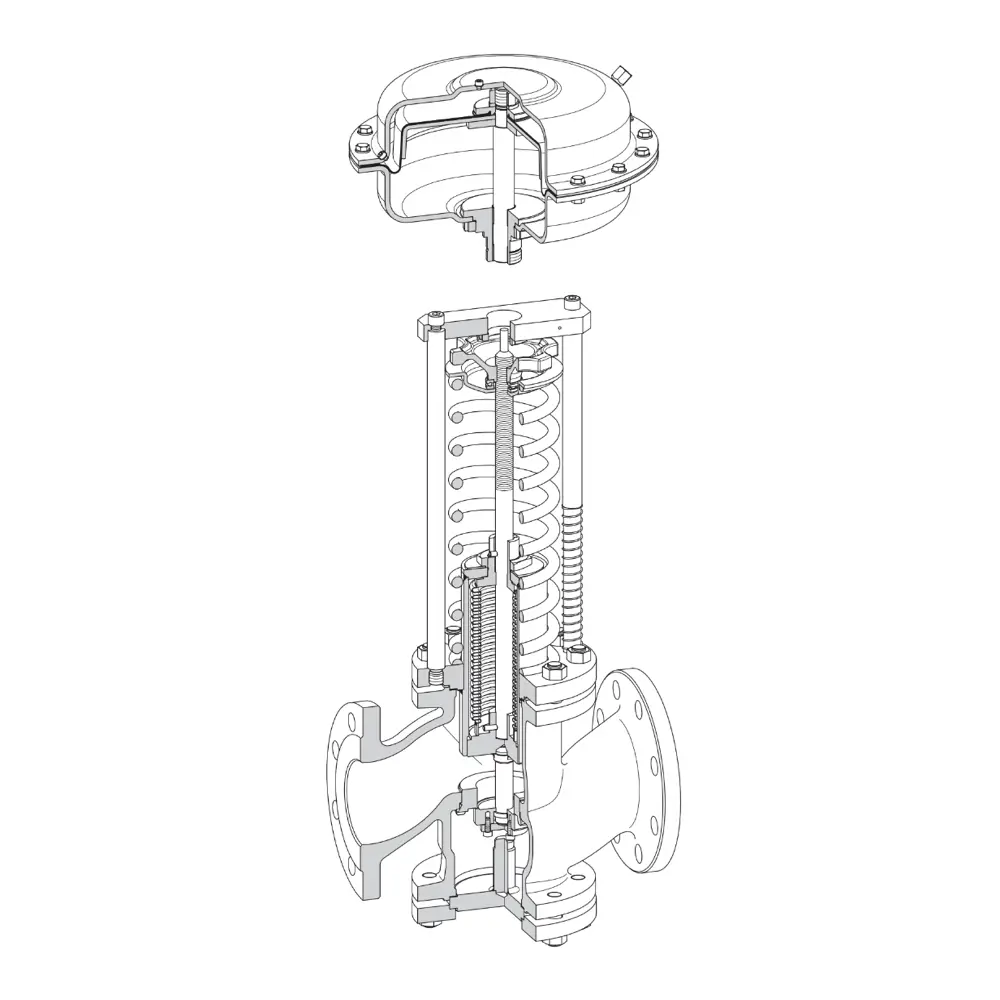

Series AP : DA Double Acting / SA Single Acting Size range : AP0 – AP12 (Ø32 mm to Ø330 mm)Actuator Stroke

– 90° with single travel adjustment ±3° (AP series) – 90° with double travel adjustment ±5° (APM series)Pressure range in pneumatic actuator

2 bar to 8 bar for Double Acting 3 bar to 8 bar for Single ActingTorque range for pneumatic actuator

2.4 – 7500 Nm (21.4 to 66875 lbf.in)Operating temperature For actuator

-20 °C to +80 °C (-4 °F to +175 °F) standardDesign reference

UNI EN 15714-3, ISO 5211, VDI / VDE 3845Flange interface

ISO 5211Stem connection

Square or polygonal shape ISO 5211Interface for pilot valve

NAMUR typeAccessories flange

VDI / VDE 3845, UNI EN 15714-3Applications

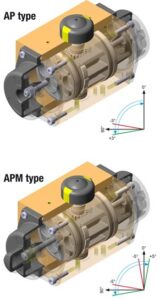

They find their best application for actuation of quarter turn valves, such as: ball valve, butterfly valve, plug valveTwo type of model: AP and APM series.

AP series, with single adjustment, allows only the adjustment of the stroke of the pistons in opening position 90° ± 3°.APM series, with double adjustment, allows to adjust the stroke of the pistons in closing and opening of ± 5°.Dual piston rack and pinion design for compact construction, symmetric mounting piston. One compact design with identical body and end caps for double acting and spring return model.Extruded aluminium body, available with two types of corrosion protection, gold anodised or hard anodised. All bodies are machined with CNC controlled machines in order to obtain the highest quality and precision.End caps and pistons are made of die-cast aluminum. End caps are painted.Pinion is made in nickel plated steel alloy. An anti-blowout system prevents the stem from slipping out of the actuator body.All moving components, are equipped with special anti-friction rings or bearing.All springs are made with an encapsulated system that avoids the risk of accidents during the disassembly phases of the actuator.Internal and external stainless steel fasteners for long term corrosion resistance.

AP series, with single adjustment, allows only the adjustment of the stroke of the pistons in opening position 90° ± 3°.APM series, with double adjustment, allows to adjust the stroke of the pistons in closing and opening of ± 5°.Dual piston rack and pinion design for compact construction, symmetric mounting piston. One compact design with identical body and end caps for double acting and spring return model.Extruded aluminium body, available with two types of corrosion protection, gold anodised or hard anodised. All bodies are machined with CNC controlled machines in order to obtain the highest quality and precision.End caps and pistons are made of die-cast aluminum. End caps are painted.Pinion is made in nickel plated steel alloy. An anti-blowout system prevents the stem from slipping out of the actuator body.All moving components, are equipped with special anti-friction rings or bearing.All springs are made with an encapsulated system that avoids the risk of accidents during the disassembly phases of the actuator.Internal and external stainless steel fasteners for long term corrosion resistance.Conform to technical specifications

ISO 5211, DIN3337 and VDI / VDE 3845 NAMUR for product interchangeability and easy mounting of solenoids valve, limit switches and other accessories.

| Pneumatic Actuator (AP0) Only Double Acting (DA) | |||

|---|---|---|---|

| ITEM | DESCRIPTION | STANDARD MATERIALS | Q.TY |

| 1 | BODY | Anodised | 1 |

| Extruded Aluminium | |||

| 2 | PISTON | Die Cast Aluminium | 2 |

| 3 | END CAP | Die Cast Aluminium | 2 |

| 4 | PINION | E.N.P. Carbon Steel | 1 |

| 5* | PISTON GUIDE | Pom Copolimer | 2 |

| 7* | LOWER PINION O-RING | Nitrile Rubber Nbr | 1 |

| 9* | UPPER PINION O-RING | Nitrile Rubber Nbr | 1 |

| 10 | PINION RETAINING RING | Enp Spring Steel | 1 |

| 11 | PINION WASHER | Nylon | 1 |

| 12* | Plug | Nitrile Rubber Nbr | 2 |

| 14 | TRAVEL STOP BOLT | Stainless Steel | 2 |

| 15* | O-RING | Nitrile Rubber Nbr | 2 |

| 16 | WASHER | Stainless Steel | 2 |

| 17 | NUT | Stainless Steel | 2 |

| 18 | END CAP SCREW | Stainless Steel | 8 |

| 19* | CUP O-RING | Nitrile Rubber Nbr | 2 |

| 20* | PISTON RING | Nylon | 2 |

| 21* | PISTON O-RING | Nitrile Rubber Nbr | 2 |

| * Suggested spare parts for maintenance included in spare parts kit | |||

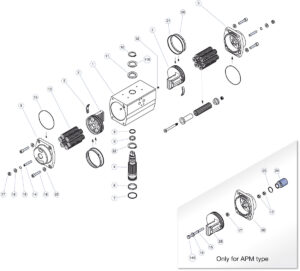

AP1 to AP10 Pneumatic Actuator Double Acting (DA) and Spring Return (SR)

| Double Acting (DA) and Spring Return (SR) | ||||

|---|---|---|---|---|

| ITEM | DESCRITPION | STANDARD MATERIALS | QUANTITY | |

| AP | APM | |||

| 1 | BODY | Anodised Extruded Aluminium | 1 | 1 |

| 2 | PISTON | Die Cast Aluminium | 2 | 1 |

| 2B | PISTON | Die Cast Aluminium | 0 | 1 |

| 3 | END CAP | Die Cast Aluminium | 2 | 1 |

| 3B | END CAP | Die Cast Aluminium | 0 | 1 |

| 4 | PINION | E.N.P. Carbon Steel | 1 | 1 |

| 5* | PISTON GUIDE | Pom Copolimer | 2 | 2 |

| 6* | LOWER PINION | Ring Nylon | 1 | 1 |

| 7* | LOWER PINION O-RING | Nitrile Rubber Nbr | 1 | 1 |

| 8* | UPPER PINION RING | Nylon | 1 | 1 |

| 9* | UPPER PINION O-RING | Nitrile Rubber Nbr | 1 | 1 |

| 10 | PINION RETAINING RING | Enp Spring Steel | 1 | 1 |

| 11 | PINION WASHER | Nylon | 1 | 1 |

| 11B | STEEL PINION WASHER (only for AP10 model) | E.N.P. Carbon Steel | 1 | 1 |

| 12* | PLUG | Nitrile Rubber Nbr | 2 | 2 |

| 13 | SPRING (Cartridge) | Spring Steel Coated | 4÷12 | 4÷12 |

| 14 | TRAVEL STOP BOLT | Stainless Steel | 2 | 1 |

| 14B | TRAVEL STOP SCREW | Stainless Steel | 0 | 1 |

| 15* | O-RING | Nitrile Rubber Nbr | 2 | 1 |

| 16 | WASHER | Stainless Steel | 2 | 2 |

| 17 | NUT | Stainless Steel | 2 | 4 |

| 18 | END CAP SCREW | Stainless Steel | 8 | 8 |

| 19* | CUP O-RING | Nitrile Rubber Nbr | 2 | 2 |

| 20 | PISTON RING | Nylon | 2 | 2 |

| 21* | PISTON O-RING | Nitrile Rubber Nbr | 2 | 2 |

| 22 | INTERNAL PINION RETAINING RING (on request) | Enp Spring Steel | 1 | 1 |

| 23 | WASHER SCREW | Stainless Steel | 4÷8 | 4÷8 |

| 24 | CUP PLUG | Aluminium | 0 | 1 |

| 25* | O-RING | Nitrile Rubber Nbr | 0 | 1 |

| *Suggested spare parts for maintenance included in spare parts kit | ||||

AP12 Pneumatic Actuator Double Acting (DA) and Spring Return (SR)

| Double Acting (DA) and Spring Return (SR) | ||||

|---|---|---|---|---|

| ITEM | DESCRITPION | STANDARD MATERIALS | QUANTITY | |

| AP | APM | |||

| 1 | BODY | Anodised Extruded Aluminium | 1 | 1 |

| 2 | PISTON | Die Cast Aluminium | 2 | 1 |

| 2B | PISTON | Die Cast Aluminium | 0 | 1 |

| 3 | END CAP | Die Cast Aluminium | 2 | 1 |

| 3B | END CAP | Die Cast Aluminium | 0 | 1 |

| 4 | PINION | E.N.P. Carbon Steel | 1 | 1 |

| 5* | PISTON GUIDE | Pom Copolimer | 4 | 4 |

| 6* | LOWER PINION RING | Nylon | 1 | 1 |

| 7* | LOWER PINION O-RING | Nitrile Rubber Nbr | 1 | 1 |

| 8* | UPPER PINION RING | Nylon | 1 | 1 |

| 9* | UPPER PINION O-RING | Nitrile Rubber Nbr | 1 | 1 |

| 10 | PINION RETAINING RING | Enp Spring Steel | 1 | 1 |

| 11 | PINION WASHER | Nylon | 1 | 1 |

| 12* | O-RING | Nitrile Rubber Nbr | 2 | 2 |

| 13 | SPRING (Cartridge) | Spring Steel Coated | 4÷12 | 4÷12 |

| 14 | TRAVEL STOP BOLT | Stainless Steel | 2 | 1 |

| 14B | TRAVEL STOP SCREW | Stainless Steel | 0 | 1 |

| 15* | O-RING | Nitrile Rubber Nbr | 2 | 1 |

| 16 | WASHER | Stainless Steel | 2 | 2 |

| 17 | NUT | Stainless Steel | 2 | 3 |

| 17B | NUT (LOW TYPE) | Stainless Steel | 0 | 1 |

| 18 | END CAP SCREW | Stainless Steel | 16 | 16 |

| 19* | CUP O-RING | Nitrile Rubber Nbr | 2 | 2 |

| 20* | PISTON RING | Nylon | 2 | 2 |

| 21* | PISTON O-RING | Nitrile Rubber Nbr | 2 | 2 |

| 22 | STEEL PINION WASHER | E.N.P. Carbon Steel | 1 | 1 |

| 23 | WASHER SCREW | Stainless Steel | 16 | 16 |

| 24 | FLANGE SCREW | Stainless Steel | 4 | 4 |

| 25 | FLANGE | Carbon Steel Coated | 1 | 1 |

| 26 | CILINDRIC PIN | Stainless Steel | 2 | 2 |

| 27 | INDICATOR or CAM | Polypropilene | 1 | 1 |

| 28 | EYE BOLT | Stainless Steel | 2 | 2 |

| 29* | O-RING | Nitrile Rubber Nbr | 0 | 1 |

| 30 | END CUP PLUG | Aluminium | 0 | 1 |

| *Suggested spare parts for maintenance included in spare parts kit | ||||

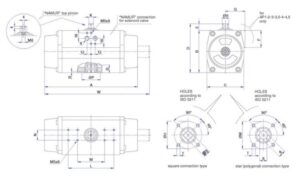

Dimensions

| MODEL | U.M. | A | W* | B | C | D | E | F | G | H | K | L | M | N | P | Q | R | ☐ S-S | T | U | V* | ISO 5211 | ISO 5211 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| H11 | std | spec | |||||||||||||||||||||

| AP1 DA/SR | mm | 142 | 162 | 67 | 60 | 87 | 20 | 42 | 41 | 12 | 8 | // | 80 | 30 | 25 | 10 | 2 | 9/11** | M5/M6 | 36/50 | 1/8” | F03/F05 | F04 |

| ins. | 5.59 | 6.38 | 2.64 | 2.36 | 3.43 | 0.79 | 1.65 | 1.61 | 0.47 | 0.31 | // | 3.15 | 1.18 | 0.98 | 0.39 | 0.08 | 0.35/0.43** | 1.42/1.97 | |||||

| AP2 DA/SR | mm | 155 | 171 | 83 | 73 | 103 | 20 | 42 | 44.5 | 12 | 8 | // | 80 | 30 | 30 / 35 | 12 | 2 | 11/14** | M5/M6 | 42/50 | 1/4” | *** | // |

| ins. | 6.10 | 6.73 | 3.27 | 2.87 | 4.06 | 0.79 | 1.65 | 1.75 | 0.47 | 0.31 | // | 3.15 | 1.18 | 1.18/1.38 | 0.47 | 0.08 | 0.43/0.55** | 1.65/1.97 | F04 or F05 | ||||

| AP3 DA/SR | mm | 213 | 240 | 100 | 85 | 120 | 20 | 50 | 49.5 | 14 | 10 | // | 80 | 30 | 35 | 16 | 2 | 14/17** | M6/M8 | 50/70 | 1/4” | F05/F07 | // |

| ins. | 8.33 | 9.45 | 3.94 | 3.35 | 4.72 | 0.79 | 1.97 | 1.95 | 0.55 | 0.39 | // | 3.15 | 1.18 | 1.38 | 0.63 | 0.12 | 0.43/0.67** | 1.97/2.76 | |||||

| AP3,5 DA/SR | mm | 236 | 268 | 110 | 98 | 130 | 20 | 50 | 53 | 19 | 14 | // | 80 | 30 | 55 | 20 | 3.5 | 17/22** | M8 | 70 | 1/4” | F07 | F05 |

| ins. | 9.29 | 10.55 | 4.33 | 3.86 | 5.12 | 0.79 | 1.97 | 2.09 | 0.75 | 0.55 | // | 3.15 | 1.18 | 2.17 | 0.79 | 0.14 | 0.67/0.87** | 2.76 | |||||

| AP4 DA/SR | mm | 276 | 304 | 125 | 110 | 145 | 20 | 50 | 58 | 19 | 14 | // | 80 | 30 | 55 | 20 | 3.5 | 17/22** | M8/M10 | 70/102 | 1/4” | F07/F10 | // |

| ins. | 10.87 | 11.97 | 4.92 | 4.33 | 5.71 | 0.79 | 1.97 | 2.28 | 0.75 | 0.55 | // | 3.15 | 1.18 | 2.17 | 0.79 | 0.14 | 0.67/0.87** | 2.76/4.02 | |||||

| AP4,5 DA/SR | mm | 310 | 350 | 142 | 128 | 172 | 30 | 58 | 69 | 28 | 20 | 130 | 80 | 30 | 70 | 24 | 3.5 | 17**/22 | M10 | 102 | 1/4” | F10 | F07 |

| ins. | 12.20 | 13.78 | 5.59 | 5.04 | 6.77 | 1.18 | 2.28 | 2.72 | 1.10 | 0.79 | 5.12 | 3.15 | 1.18 | 2.76 | 0.94 | 0.14 | 0.67**/0.87 | 4.02 | |||||

| AP5 DA/SR | mm | 366 | 405 | 155 | 140 | 185 | 30 | // | // | 28 | 20 | 130 | 80 | 30 | 70 | 24 | 3.5 | 17**/22 | M10 | 102 | 1/4” | F10 | F07/F12 |

| ins. | 14.41 | 15.94 | 6.10 | 5.51 | 7.28 | 1.18 | // | // | 1.10 | 0.79 | 5.12 | 3.15 | 1.18 | 2.76 | 0.94 | 0.14 | 0.67**/0.87 | 4.02 | |||||

| AP5,5 DA/SR | mm | 388 | 442 | 176 | 160 | 206 | 30 | // | // | 36 | 28 | 130 | 80 | 30 | 85 | 29 | 3.5 | 22**/27 | M12 | 125 | 1/4” | F12 | F10 |

| ins. | 15.27 | 17.40 | 6.93 | 6.30 | 8.11 | 1.18 | // | // | 1.42 | 1.10 | 5.12 | 3.15 | 1.18 | 3.35 | 1.14 | 0.14 | 0.87**/1.06 | 4.92 | |||||

| AP6 DA/SR | mm | 468 | 500 | 200 | 175 | 230 | 30 | // | // | 36 | 28 | 130 | 80 | 30 | 85 | 29 | 3.5 | 22**/27 | M12 | 125 | 1/4” | F12 | F10 |

| ins. | 18.42 | 19.68 | 7.87 | 6.89 | 9.06 | 1.18 | // | // | 1.42 | 1.10 | 5.12 | 3.15 | 1.18 | 3.35 | 1.14 | 0.14 | 0.87**/1.06 | 4.92 | |||||

| AP8 DA/SR | mm | 563 | 612 | 250 | 215 | 300 | 50 | // | // | 48 | 32 | 130 | // | 30 | 100 | 38 | 5 | 27**/36 | M16 | 140 | F14 | F14 | F12 |

| ins. | 22.16 | 24.09 | 9.84 | 8.46 | 11.81 | 1.97 | // | // | 1.89 | 1.26 | 5.12 | // | 1.18 | 3.94 | 1.50 | 0.20 | 1.06**/1.42 | 5.51 | |||||

| AP10 DA/SR | mm | 750 | 838 | 335 | 290 | 385 | 50 | // | // | 48 | 32 | 130 | // | 30 | 130 | 50 | 5 | 36**/46 | M20 | 165 | 1/4” | F16 | F14 |

| ins. | 29.53 | 32.99 | 13.19 | 11.42 | 15.16 | 1.97 | // | // | 1.89 | 1.26 | 5.12 | // | 1.18 | 5.12 | 1.97 | 0.20 | 1.42**/1.81 | 6.50 | |||||

| W* dimension only for APM series | ** S dimension with (**) only request | V* dimensions threated GAS or NPT | *** To be chosen when ordering | ||||||||||||||||||||

Torque ratings

| DOUBLE ACTING TORQUE RATINGS (DA) | ||||||||

|---|---|---|---|---|---|---|---|---|

| OPERATING PRESSURE | ||||||||

| MODEL | bar | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| p.s.i. | 30 | 44 | 58 | 73 | 87 | 102 | 116 | |

| AP0 DA | N m | 2.4 | 3.6 | 4.8 | 6 | 7.3 | 8.5 | 9.7 |

| Ib f.In | 21.4 | 32.1 | 42.8 | 53.5 | 65.1 | 75.8 | 86.5 | |

| AP1 DA | N m | 5.9 | 8.9 | 11.8 | 14.8 | 17.7 | 21.7 | 24.8 |

| Ib f.In | 52.6 | 79.3 | 105.2 | 132 | 157.8 | 193.5 | 221.1 | |

| AP2 DA | N m | 9.4 | 14.1 | 18.8 | 23.5 | 28.2 | 32.9 | 37.6 |

| Ib f.In | 83.8 | 125.7 | 167.7 | 209.6 | 251.5 | 293.5 | 335.4 | |

| AP3 DA | N m | 20 | 30 | 40 | 50 | 60 | 70 | 80 |

| Ib f.In | 178.4 | 267.6 | 356.8 | 446 | 535.2 | 624.4 | 713.6 | |

| AP3.5 DA | N m | 34 | 51 | 68 | 85 | 102 | 119 | 136 |

| Ib f.In | 303.3 | 454.9 | 606.5 | 758.2 | 909 | 1061.5 | 1213.2 | |

| AP4 DA | N m | 48 | 71 | 95 | 119 | 142 | 168 | 192 |

| Ib f.In | 428.2 | 633.3 | 847.4 | 1061 | 1266.6 | 1498.5 | 1712.6 | |

| AP4.5 DA | N m | 87.2 | 130.8 | 174.4 | 218 | 261.6 | 305.2 | 348.8 |

| Ib f.In | 777.8 | 1166.7 | 1555.6 | 1944.5 | 2333.4 | 2722.3 | 3111.2 | |

| AP5 DA | N m | 111 | 167 | 222 | 278 | 333 | 388.5 | 444 |

| Ib f.In | 990.1 | 1489.6 | 1980.2 | 2479.7 | 2970.4 | 3465.4 | 3960.5 | |

| AP5.5 DA | N m | 157.6 | 236.4 | 315.3 | 394.1 | 473 | 551.8 | 630.6 |

| Ib f.In | 1405.7 | 2108.6 | 2812.4 | 3515.3 | 4219.1 | 4922 | 5624.9 | |

| AP6 DA | N m | 227 | 340 | 454 | 567 | 680 | 794.5 | 908 |

| Ib f.In | 2024.8 | 3032.8 | 4049.6 | 5057.6 | 6065.6 | 7087 | 8099.4 | |

| AP8 DA | N m | 426 | 638 | 851 | 1064 | 1276 | 1491 | 1704 |

| Ib f.In | 3800 | 5691 | 7591 | 9491 | 11382 | 13299 | 15200 | |

| AP10 DA | N m | 1078 | 1617 | 2156 | 2695 | 3234 | 3773 | 4312 |

| Ib f.In | 9615.8 | 14423.6 | 19231.5 | 24039.4 | 28847.3 | 33655.2 | 38463 | |

| AP12 DA | N m | 1880 | 2820 | 3760 | 4701 | 5641 | 6581 | 7522 |

| Ib f.In | 16770 | 25155 | 33539 | 41933 | 50318 | 58703 | 67096 | |

| SPRING RETURN TORQUE RATINGS (SR) | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MODEL | U.M. | SUPPLY PRESSURE | ||||||||||||||

| OF SPRINGS FOR EACH SIDE OF CAP | bar | 3 | 4 | 5 | 6 | 7 | 8 | SPRING STROKE | ||||||||

| p.s.i. | 44 | 58 | 73 | 87 | 102 | 118 | ||||||||||

| 0° | 90° | 0° | 90° | 0° | 90° | 0° | 90° | 0° | 90° | 0° | 90° | 90° | 0° | |||

| AP1 SR | 2 | N m | 6.5 | 5.4 | 9.4 | 8.3 | 12.4 | 11.3 | 15.3 | 14.2 | 19.3 | 18.2 | 22.4 | 21.3 | 3.5 | 2.4 |

| lb f.in | 58.0 | 48.2 | 83.8 | 74.0 | 110.6 | 100.8 | 136.5 | 126.7 | 172.2 | 162.3 | 199.8 | 190.0 | 31.2 | 21.4 | ||

| 3 | N m | 5.3 | 3.7 | 8.2 | 6.6 | 11.2 | 9.6 | 14.1 | 12.5 | 18.1 | 16.5 | 21.2 | 19.6 | 5.2 | 3.6 | |

| lb f.in | 47.3 | 33.0 | 73.1 | 58.9 | 99.9 | 85.6 | 125.8 | 111.5 | 161.5 | 147.2 | 189.1 | 174.8 | 46.4 | 32.1 | ||

| 4 | N m | 4.1 | 1.9 | 7 | 4.8 | 10 | 7.8 | 12.9 | 10.7 | 16.9 | 14.7 | 20 | 17.8 | 7 | 4.8 | |

| lb f.in | 36.6 | 16.9 | 62.4 | 42.8 | 89.2 | 69.6 | 115.1 | 95.4 | 150.7 | 131.1 | 178.4 | 158.8 | 62.4 | 42.8 | ||

| 5 | N m | // | // | 3.1 | 2.7 | 8.8 | 6.1 | 11.7 | 9 | 15.7 | 13 | 18.8 | 16.1 | 8.7 | 6 | |

| lb f.in | // | // | 27.7 | 24.1 | 78.5 | 54.4 | 104.4 | 80.3 | 140.0 | 116.0 | 167.7 | 143.6 | 77.6 | 53.5 | ||

| 6 | N m | // | // | // | // | 7.6 | 4.3 | 10.5 | 7.2 | 14.5 | 11.2 | 17.6 | 14.3 | 10.5 | 7.2 | |

| lb f.in | // | // | // | // | 67.8 | 38.4 | 93.7 | 64.2 | 129.3 | 99.9 | 157.0 | 127.6 | 93.7 | 64.2 | ||

| AP2 SR | 2 | N m | 10.3 | 8.5 | 15 | 13.2 | 19.7 | 17.9 | 24.4 | 22.6 | 29.1 | 27.3 | 33.8 | 32 | 5.6 | 3.8 |

| lb f.in | 91.9 | 75.8 | 133.8 | 117.7 | 175.7 | 159.7 | 217.6 | 201.6 | 259.6 | 243.5 | 301.5 | 285.4 | 50.0 | 33.9 | ||

| 3 | N m | 8.4 | 5.7 | 13.1 | 10.4 | 17.8 | 15.1 | 22.5 | 19.8 | 27.2 | 24.5 | 31.9 | 29.2 | 8.4 | 5.7 | |

| lb f.in | 74.9 | 50.8 | 116.9 | 92.8 | 158.8 | 134.7 | 200.7 | 176.6 | 242.6 | 218.5 | 284.5 | 260.5 | 74.9 | 50.8 | ||

| 4 | N m | // | // | 11.2 | 7.6 | 15.9 | 12.3 | 20.6 | 17 | 25.3 | 21.7 | 30 | 26.4 | 11.2 | 7.6 | |

| lb f.in | // | // | 99.9 | 67.8 | 141.8 | 109.7 | 183.8 | 151.6 | 225.7 | 193.6 | 267.6 | 235.5 | 99.9 | 67.8 | ||

| 5 | N m | // | // | // | // | 14 | 9.5 | 18.7 | 14.2 | 23.4 | 18.9 | 28.1 | 23.6 | 14 | 9.5 | |

| lb f.in | // | // | // | // | 124.9 | 84.7 | 166.8 | 126.7 | 208.7 | 168.6 | 250.7 | 210.5 | 124.9 | 84.7 | ||

| 6 | N m | // | // | // | // | 12.1 | 6.7 | 16.8 | 11.4 | 21.5 | 16.1 | 26.2 | 20.8 | 16.8 | 11.4 | |

| lb f.in | // | // | // | // | 107.9 | 59.8 | 149.9 | 101.7 | 191.8 | 143.6 | 233.7 | 185.5 | 149.9 | 101.7 | ||

| A3 SR | 2 | N m | 22 | 18 | 32 | 28 | 42 | 38 | 52 | 48 | 62 | 58 | 72 | 68 | 12 | 8 |

| lb f.in | 196.2 | 160.6 | 285.4 | 249.8 | 374.6 | 339.0 | 463.8 | 428.2 | 553.0 | 517.4 | 642.2 | 606.6 | 107.0 | 71.4 | ||

| 3 | N m | 18 | 12 | 28 | 22 | 38 | 32 | 48 | 42 | 58 | 52 | 68 | 62 | 18 | 12 | |

| lb f.in | 160.6 | 107.0 | 249.8 | 196.2 | 339.0 | 285.4 | 428.2 | 374.6 | 517.4 | 463.8 | 606.6 | 553.0 | 160.6 | 107.0 | ||

| 4 | N m | // | // | 24 | 16 | 34 | 26 | 44 | 36 | 54 | 46 | 64 | 56 | 24 | 16 | |

| lb f.in | // | // | 214.1 | 142.7 | 303.3 | 231.9 | 392.5 | 321.1 | 481.7 | 410.3 | 570.9 | 499.5 | 214.1 | 142.7 | ||

| 5 | N m | // | // | // | // | 30 | 20 | 40 | 30 | 50 | 40 | 60 | 50 | 30 | 20 | |

| lb f.in | // | // | // | // | 267.6 | 178.4 | 356.8 | 267.6 | 446.0 | 356.8 | 535.2 | 446.0 | 267.6 | 178.4 | ||

| 6 | N m | // | // | // | // | 26 | 14 | 36 | 24 | 46 | 34 | 56 | 44 | 36 | 24 | |

| lb f.in | // | // | // | // | 231.9 | 124.9 | 321.1 | 214.1 | 410.3 | 303.3 | 499.5 | 392.5 | 321.1 | 214.1 | ||

| AP3,5 SR | 2 | N m | 41.5 | 30 | 58.5 | 47 | 75.5 | 64 | 92.5 | 81 | 109.5 | 98 | 126.5 | 115 | 21 | 9.5 |

| lb f.in | 370.2 | 267.6 | 521.8 | 419.2 | 673.5 | 570.9 | 825.1 | 722.5 | 976.7 | 874.2 | 1128.4 | 1025.8 | 187.3 | 84.7 | ||

| 3 | N m | 32 | 20 | 49 | 37 | 66 | 54 | 83 | 71 | 100 | 88 | 117 | 105 | 31 | 19 | |

| lb f.in | 285.4 | 178.4 | 437.1 | 330.0 | 588.7 | 481.7 | 740.4 | 633.3 | 892.0 | 785.0 | 1043.6 | 936.6 | 276.5 | 169.5 | ||

| 4 | N m | // | // | 43 | 20 | 60 | 37 | 77 | 54 | 94 | 71 | 111 | 88 | 48 | 25 | |

| lb f.in | // | // | 383.6 | 178.4 | 535.2 | 330.0 | 686.8 | 481.7 | 838.5 | 633.3 | 990.1 | 785.0 | 428.2 | 223.0 | ||

| 5 | N m | // | // | // | // | 53 | 33 | 70 | 50 | 87 | 67 | 104 | 84 | 52 | 32 | |

| lb f.in | // | // | // | // | 472.8 | 294.4 | 624.4 | 446.0 | 776.0 | 597.6 | 927.7 | 749.3 | 463.8 | 285.4 | ||

| 6 | N m | // | // | // | // | 47 | 22 | 64 | 39 | 81 | 56 | 106.4 | 73 | 63 | 38 | |

| lb f.in | // | // | // | // | 419.2 | 196.2 | 570.9 | 347.9 | 722.5 | 499.5 | 949.1 | 651.2 | 562.0 | 339.0 | ||

| AP4 SR | 2 | N m | 52.7 | 42.4 | 76.7 | 66.4 | 100.7 | 90.4 | 123.7 | 113.4 | 149.7 | 139.4 | 173.7 | 175.2 | 28.6 | 18.3 |

| lb f.in | 470.1 | 378.2 | 684.2 | 592.3 | 898.2 | 806.4 | 1103.4 | 1011.5 | 1335.3 | 1243.4 | 1549.4 | 1562.8 | 255.1 | 163.2 | ||

| 3 | N m | 43 | 28 | 67 | 52 | 91 | 76 | 114 | 99 | 140 | 125 | 164 | 153.6 | 43 | 28 | |

| lb f.in | 383.6 | 249.8 | 597.6 | 463.8 | 811.7 | 677.9 | 1016.9 | 883.1 | 1248.8 | 1115.0 | 1462.9 | 1370.1 | 383.6 | 249.8 | ||

| 4 | N m | // | // | 58 | 38 | 82 | 62 | 105 | 85 | 131 | 111 | 155 | 132 | 57 | 37 | |

| lb f.in | // | // | 517.4 | 339.0 | 731.4 | 553.0 | 936.6 | 758.2 | 1168.5 | 990.1 | 1382.6 | 1177.4 | 508.4 | 330.0 | ||

| 5 | N m | // | // | // | // | 73 | 47 | 96 | 70 | 122 | 96 | 146 | 110.4 | 72 | 46 | |

| lb f.in | // | // | // | // | 651.2 | 419.2 | 856.3 | 624.4 | 1088.2 | 856.3 | 1302.3 | 948.8 | 642.2 | 410.3 | ||

| 6 | N m | // | // | // | // | 64 | 33 | 87 | 56 | 113 | 82 | 137 | 88.8 | 86 | 55 | |

| lb f.in | // | // | // | // | 570.9 | 294.4 | 776.0 | 499.5 | 1008.0 | 731.4 | 1222.0 | 792.1 | 767.1 | 490.6 | ||

| A4,5 SR | 2 | N m | 96.8 | 77.5 | 140.4 | 121.1 | 184 | 164.7 | 227.6 | 208.3 | 271.2 | 251.9 | 314.8 | 295.5 | 53.3 | 34 |

| lb f.in | 950.6 | 761.1 | 1378.7 | 1189.2 | 1806.9 | 1617.4 | 2235.0 | 2045.5 | 2663.2 | 2473.7 | 3091.3 | 2901.8 | 475.4 | 303.2 | ||

| 3 | N m | 79.8 | 50.9 | 123.4 | 94.5 | 167 | 138.1 | 210.6 | 181.7 | 254.2 | 225.3 | 297.8 | 268.9 | 79.9 | 51 | |

| lb f.in | 783.6 | 499.8 | 1211.8 | 928.0 | 1639.9 | 1356.1 | 2068.1 | 1784.3 | 2496.2 | 2212.4 | 2924.4 | 2640.6 | 712.7 | 454.9 | ||

| 4 | N m | // | // | 106.4 | 67.8 | 150 | 111.4 | 193.6 | 155 | 237.2 | 198.6 | 280.8 | 242.2 | 106.6 | 68 | |

| lb f.in | // | // | 1044.8 | 665.8 | 1473.0 | 1093.9 | 1901.2 | 1522.1 | 2329.3 | 1950.3 | 2757.5 | 2378.4 | 950.8 | 606.5 | ||

| 5 | N m | // | // | // | // | 133 | 84.7 | 176.6 | 128.3 | 220.2 | 171.9 | 263.8 | 215.5 | 133.3 | 85 | |

| lb f.in | // | // | // | // | 1306.1 | 831.8 | 1734.2 | 1259.9 | 2162.4 | 1688.1 | 2590.5 | 2116.2 | 1189.0 | 758.2 | ||

| 6 | N m | // | // | // | // | 116 | 58 | 159.6 | 101.6 | 203.2 | 145.2 | 246.8 | 188.8 | 160 | 102 | |

| lb f.in | // | // | // | // | 1139.1 | 569.6 | 1567.3 | 997.7 | 1995.4 | 1425.9 | 2423.6 | 1854.0 | 1427.2 | 909.8 | ||

| AP5 SR | 2 | N m | 123.7 | 99.4 | 178.7 | 154.4 | 234.7 | 210.4 | 289.7 | 265.4 | 345.2 | 320.9 | 400.7 | 376.4 | 67.6 | 43.3 |

| lb f.in | 1103.4 | 886.6 | 1594.0 | 1377.2 | 2093.5 | 1876.8 | 2584.1 | 2367.4 | 3079.2 | 2862.4 | 3574.2 | 3357.5 | 603.0 | 386.2 | ||

| 3 | N m | 103 | 66 | 158 | 121 | 214 | 177 | 269 | 232 | 324.5 | 287.5 | 380 | 343 | 101 | 64 | |

| lb f.in | 918.8 | 588.7 | 1409.4 | 1079.3 | 1908.9 | 1578.8 | 2399.5 | 2069.4 | 2894.5 | 2564.5 | 3389.6 | 3059.6 | 900.9 | 570.9 | ||

| 4 | N m | // | // | 136 | 87 | 192 | 143 | 247 | 198 | 302.5 | 253.5 | 358 | 309 | 135 | 86 | |

| lb f.in | // | // | 1231.1 | 776.0 | 1712.6 | 1275.6 | 2203.2 | 1766.2 | 2698.3 | 2261.2 | 3193.4 | 2756..3 | 1204.2 | 767.1 | ||

| 5 | N m | // | // | // | // | 170 | 109 | 225 | 164 | 280.5 | 219.5 | 336 | 275 | 169 | 108 | |

| lb f.in | // | // | // | // | 1516.4 | 972.3 | 2007.0 | 1462.9 | 2502.1 | 1957.9 | 2997.1 | 2453.0 | 1507.5 | 963.4 | ||

| 6 | N m | // | // | // | // | 148 | 75 | 203 | 130 | 258.5 | 185.5 | 314 | 241 | 203 | 130 | |

| lb f.in | // | // | // | // | 1320.2 | 669.0 | 1810.8 | 1159.6 | 2305.8 | 1654.7 | 2800.9 | 2149.7 | 1810.8 | 1159.6 | ||

| AP5,5 SR | 2 | N m | 179.8 | 136.4 | 258.7 | 215.3 | 337.5 | 294.1 | 416.4 | 373 | 495.2 | 451.8 | 574 | 530.6 | 100 | 56.6 |

| lb f.in | 1765.6 | 1339.4 | 2540.4 | 2114.2 | 3314.3 | 2888.1 | 4089.0 | 3662.9 | 4862.9 | 4436.7 | 5636.7 | 5210.5 | 892.0 | 504.8 | ||

| 3 | N m | 151.5 | 86.4 | 230.4 | 165.3 | 309.2 | 244.1 | 388.1 | 323 | 466.9 | 401.8 | 545.7 | 480.6 | 150 | 84.9 | |

| lb f.in | 1487.7 | 848.4 | 2262.5 | 1623.2 | 3036.3 | 2397.1 | 3811.1 | 3171.9 | 4585.0 | 3945.7 | 5358.8 | 4719.5 | 1338.0 | 757.3 | ||

| 4 | N m | // | // | 202 | 115.3 | 280.8 | 194.1 | 359.7 | 273 | 438.5 | 351.8 | 517.3 | 430.6 | 200 | 113.3 | |

| lb f.in | // | // | 1983.6 | 1132.2 | 2757.5 | 1906.1 | 3532.3 | 2680.9 | 4306.1 | 3454.7 | 5079.9 | 4228.5 | 1784.0 | 1010.6 | ||

| 5 | N m | // | // | // | // | 252.5 | 144.1 | 331.4 | 223 | 410.2 | 301.8 | 489 | 380.6 | 250 | 141.6 | |

| lb f.in | // | // | // | // | 2479.6 | 1415.1 | 3254.3 | 2189.9 | 4028.2 | 2963.7 | 4802.0 | 3737.5 | 2230.0 | 1263.0 | ||

| 6 | N m | // | // | // | // | 224.1 | 94.1 | 303 | 173 | 381.8 | 251.8 | 460.6 | 330.6 | 300 | 170 | |

| lb f.in | // | // | // | // | 2200.7 | 924.1 | 2975.5 | 1698.9 | 3749.3 | 2472.7 | 4523.1 | 3246.5 | 2676.0 | 1516.4 | ||

| AP6 SR | 2 | N m | 257 | 200 | 371 | 314 | 484 | 427 | 597 | 540 | 711.5 | 654.5 | 825 | 768 | 140 | 83 |

| lb f.in | 2292.4 | 1784.0 | 3309.3 | 2800.9 | 4317.3 | 3808.8 | 5325.2 | 4816.8 | 6346.6 | 5838.1 | 7359.0 | 6850.6 | 1248.8 | 740.4 | ||

| 3 | N m | 215 | 130 | 329 | 244 | 442 | 357 | 555 | 470 | 669.5 | 584.5 | 783 | 698 | 210 | 125 | |

| lb f.in | 1917.8 | 1159.6 | 2934.7 | 2176.5 | 3942.6 | 3184.4 | 4950.6 | 4192.4 | 5971.9 | 5213.7 | 6984.4 | 6226.2 | 1873.2 | 1115.0 | ||

| 4 | N m | // | // | 287 | 174 | 400 | 287 | 513 | 400 | 627.5 | 514.5 | 741 | 628 | 280 | 167 | |

| lb f.in | // | // | 2560.0 | 1552.1 | 3568.0 | 2560.0 | 4576.0 | 3568.0 | 5597.3 | 4589.3 | 6609.7 | 5601.8 | 2497.6 | 1489.6 | ||

| 5 | N m | // | // | // | // | 358 | 217 | 471 | 330 | 585.5 | 444.5 | 699 | 558 | 350 | 209 | |

| lb f.in | // | // | // | // | 3193.4 | 1935.6 | 4201.3 | 2943.6 | 5222.7 | 3964.9 | 6235.1 | 4977.4 | 3122.0 | 1864.3 | ||

| 6 | N m | // | // | // | // | 316 | 147 | 429 | 260 | 543.5 | 374.5 | 657 | 488 | 420 | 251 | |

| lb f.in | // | // | // | // | 2818.7 | 1311.2 | 3826.7 | 2319.2 | 4848.0 | 3340.5 | 5860.4 | 4353.0 | 3746.4 | 2238.9 | ||

| AP8 SR | 2 | N m | 478 | 386 | 691 | 599 | 904 | 812 | 1116 | 1024 | 1331 | 1239 | 1704 | 1452 | 252 | 160 |

| lb f.in | 4263.8 | 3443.1 | 6163.7 | 5343.1 | 8063.7 | 7243.0 | 9954.7 | 9134.1 | 11872.5 | 11051.9 | 15199.7 | 12951.8 | 2247.8 | 1427.2 | ||

| 3 | N m | 398 | 260 | 611 | 473 | 824 | 686 | 1036 | 898 | 1251 | 1113 | 1464 | 1326 | 378 | 240 | |

| lb f.in | 3550.2 | 2319.2 | 5450.1 | 4219.2 | 7350.1 | 6119.1 | 9241.1 | 8010.2 | 11158.9 | 9928.0 | 13058.9 | 11827.9 | 3371.8 | 2140.8 | ||

| 4 | N m | // | // | 531 | 347 | 744 | 560 | 956 | 772 | 1171 | 987 | 1384 | 1200 | 504 | 320 | |

| lb f.in | // | // | 4736.5 | 3095.2 | 6636.5 | 4995.2 | 8527.5 | 6886.2 | 10445.3 | 8804.0 | 12345.3 | 10704.0 | 4495.7 | 2854.4 | ||

| 5 | N m | // | // | // | // | 664 | 434 | 876 | 646 | 1091 | 861 | 1304 | 1074 | 630 | 400 | |

| lb f.in | // | // | // | // | 5922.9 | 3871.3 | 7813.9 | 5762.3 | 9731.7 | 7680.1 | 11631.7 | 9580.1 | 5619.6 | 3568.0 | ||

| 6 | N m | // | // | // | // | 584 | 308 | 796 | 520 | 1011 | 735 | 1224 | 948 | 756 | 480 | |

| lb f.in | // | // | // | // | 5209.3 | 2747.4 | 7100.3 | 4638.4 | 9018.1 | 6556.2 | 10918.1 | 8456.2 | 6743.5 | 4281.6 | ||

| AP10 SR | 2 | N m | 1181 | 957 | 1720 | 1496 | 2259 | 2035 | 2798 | 2574 | 3337 | 3113 | 3876 | 3652 | 660 | 436 |

| lb f.in | 11597.4 | 9397.7 | 16890.4 | 14690.7 | 22183.4 | 19983.7 | 27476.4 | 25276.7 | 32769.3 | 30569.7 | 38062.3 | 35862.6 | 6481.2 | 4281.5 | ||

| 3 | N m | 963 | 628 | 1502 | 1167 | 2041 | 1706 | 2580 | 2245 | 3119 | 2784 | 3658 | 3323 | 989 | 654 | |

| lb f.in | 9456.7 | 6167.0 | 14749.6 | 11459.9 | 20042.6 | 16752.9 | 25335.6 | 22045.9 | 30628.6 | 27338.9 | 35921.6 | 32631.9 | 9712.0 | 6422.3 | ||

| 4 | N m | // | // | 1284 | 837 | 1823 | 1376 | 2362 | 1915 | 2901 | 2454 | 3440 | 2993 | 1319 | 872 | |

| lb f.in | // | // | 12608.9 | 8219.3 | 17901.9 | 13512.3 | 23194.8 | 18805.3 | 28487.8 | 24098.3 | 33780.8 | 29391.3 | 12952.6 | 8563.0 | ||

| 5 | N m | // | // | // | // | 1605 | 1046 | 2144 | 1585 | 2683 | 2124 | 3222 | 2663 | 1649 | 1090 | |

| lb f.in | // | // | // | // | 15761.1 | 10271.7 | 21054.1 | 15564.7 | 26347.1 | 20857.7 | 31640.0 | 26150.7 | 16193.2 | 10703.8 | ||

| 6 | N m | // | // | // | // | // | // | 1909 | 1254 | 2448 | 1793 | 2987 | 2332 | 1980 | 1325 | |

| lb f.in | // | // | // | // | // | // | 18746.4 | 12314.3 | 24039.4 | 17607.3 | 29332.3 | 22900.2 | 19443.6 | 13011.5 | ||

| A12 SR | 2 | N m | 2082 | 1723 | 3022 | 2663 | 3963 | 3604 | 4903 | 4544 | 5843 | 5484 | 6783 | 6424 | 1097 | 738 |

| lb f.in | 20445.2 | 16919.9 | 29676.0 | 26150.7 | 38916.7 | 35391.3 | 48147.5 | 44622.1 | 57378.3 | 53852.9 | 66609.1 | 63083.7 | 10772.5 | 7247.2 | ||

| 3 | N m | 1715 | 1174 | 2655 | 2114 | 3596 | 3055 | 4536 | 3995 | 5476 | 4935 | 6416 | 5875 | 1646 | 1105 | |

| lb f.in | 16841.3 | 11528.7 | 26072.1 | 20759.5 | 35312.7 | 30000.1 | 44543.5 | 39230.9 | 53774.3 | 48461.7 | 63005.1 | 57692.5 | 16163.7 | 10851.1 | ||

| 4 | N m | // | // | 2286 | 1565 | 3227 | 2506 | 4167 | 3446 | 5107 | 4386 | 6047 | 5326 | 2195 | 1474 | |

| lb f.in | // | // | 22448.5 | 15368.3 | 31689.1 | 24608.9 | 40919.9 | 33839.7 | 50150.7 | 43070.5 | 59381.5 | 52301.3 | 21554.9 | 14474.7 | ||

| 5 | N m | // | // | // | // | 2859 | 1958 | 3799 | 2898 | 4739 | 3838 | 5679 | 4778 | 2743 | 1842 | |

| lb f.in | // | // | // | // | 28075.4 | 19227.6 | 37306.2 | 28458.4 | 46537.0 | 37689.2 | 55767.8 | 46920.0 | 26936.3 | 18088.4 | ||

| 6 | N m | // | // | // | // | // | // | 3430 | 2349 | 4370 | 3289 | 5310 | 4229 | 3292 | 2211 | |

| lb f.in | // | // | // | // | // | // | 33682.6 | 23067.2 | 42913.4 | 32298.0 | 52144.2 | 41528.8 | 32327.4 | 21712.0 | ||

| NOTE: The output torque of selected actuator mentioned in the table are suitable also for APM series and the value should never be less the required valve torque. | ||||||||||||||||

Related products

-

FLOWSERVE | 5801 | PRV with actuator

฿0.00 Add to cart -

KLQD | AT Series | Pneumatic-Actuator

฿1.00 Select options This product has multiple variants. The options may be chosen on the product page